Our Plant in Swindon is an integral part of BMW Group’s production network, producing parts and panels made for the cars, which are then assembled at Plant Oxford and in the BMW Group’s global production network. In fact, 80% of the body components for the MINI – including all the skin panels and closure assemblies – originate at BMW Group Plant Swindon.

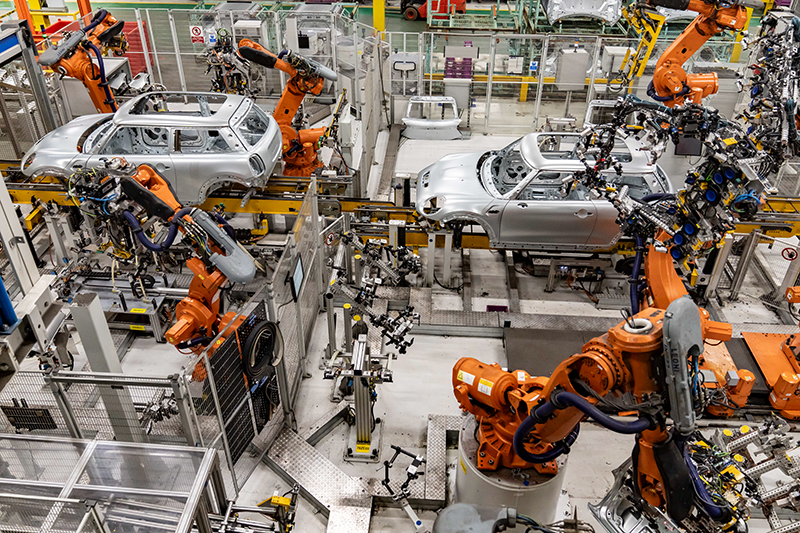

Currently, the state-of-the-art facilities at Swindon – where the focus is on two key areas of production: the Press Shop and Sub Assembly, produce for 20 different MINI and BMW models. Sub Assembly manufactures all ‘hang-on parts’ such as doors, bonnets, tailgates, fenders, for the MINIs produced at Plant Oxford. Around 500 people work at the Swindon Plant, and in 2023 they produced nearly 33 million panels, and just over 3 million sub-assemblies.

BMW Group Plant Swindon is approximately one and a half hours west of London by car, located in the Stratton St Margaret area of the borough. The site opened in 1955 as an extension to the Oxford Plant, producing pressed steel. More recently, in 2022 a new press shop and logistics hall at Plant Swindon with a new automated steel pressing facility were opened with the latest press-shop technology, allowing the site to take its performance to the next level, and to continue as a vital member of BMW Group’s international production network.